Hydraulic cylinders are known for their reliability under certain conditions. Of course, the long-term function of a hydraulic cylinder depends on how it is manufactured. Research has shown that a properly designed hydraulic cylinder, manufactured using the best manufacturing processes, will function flawlessly for a lifetime without disturbing you.

This is only possible if the hydraulic cylinders are checked and maintained regularly. You can also check for the best hydraulic cylinders through the web.

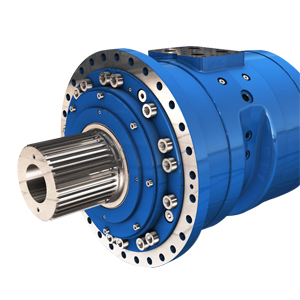

Image Source: Google

They know that hydraulic systems are complicated and so is maintenance. This article is about the general maintenance required for hydraulic cylinder systems.

Check for bent rods and adjust

Bent rods are very rare in hydraulic cylinder systems because the only way to change their shape is through a design flaw. A common cause of bent rods is insufficient rod diameter or incorrect installation position. Bending rods can also occur due to poor quality materials used to make hydraulic cylinder systems.

Inflate cylindrical tube with a balloon

The working pressure of the hydraulic cylinder has a great influence on the expansion of the cylinder tube. The balloon tube causes the seal to stop and the liquid to leak. If this problem is ignored, the efficiency of the hydraulic cylinder will be greatly reduced.

Inspection and maintenance of all these parts ensure long service life and maximum efficiency of hydraulic cylinders.