Gas turbine fixtures are commonly used in power plants, aircraft, and other industrial applications. They can be complex and challenging to troubleshoot, but there are a few steps that can help you identify and fix the issue.

Repair or Replace the Component: After performing the diagnostic tests, if it is determined that the problem is due to a faulty component, then it is necessary to either repair or replace the component. Depending on the severity of the malfunction, it may be necessary to replace the entire gas turbine fixture.

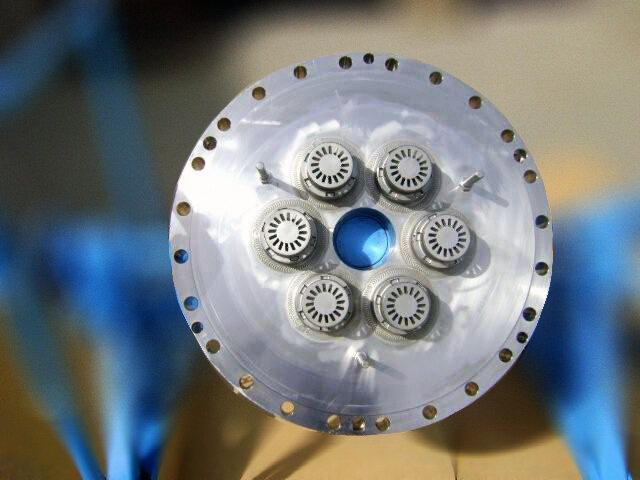

Image Source:Google

Identify the Problem: The first step in troubleshooting a gas turbine fixture is to identify the problem. This can be done by checking the system for any visible signs of damage or malfunction, such as oil or fuel leaks, or any other signs of corrosion or damage. It is also important to check the system’s readings to identify any abnormal readings or any other indicators of a malfunction.

Perform Diagnostic Tests: Once the problem has been identified, the next step is to perform a series of diagnostic tests to further investigate the issue. This can include checking the gas turbine fixture’s temperature, pressure, and vibration levels, as well as any other readings that may provide clues about the source of the problem.

Monitor the System: After the gas turbine fixture has been repaired or replaced, it is important to monitor the system for a period of time to ensure that the problem has been fixed. This can be done by regularly checking the system’s readings and temperatures, as well as any other indicators of a malfunction.